Spring Energized Seals

Whether the challenge is sealing harsh chemicals, extreme temperature, high speed, or variable pressure, Chesterton engineers will design a high performance product to meet your specific needs.

|

|

Series 100 CantileverSeries 100 includes a V-shaped spring with a linear load curve and wide deflection range which makes this our most versatile model. Good for highly dynamic reciprocating and rotary applications. |

|

|

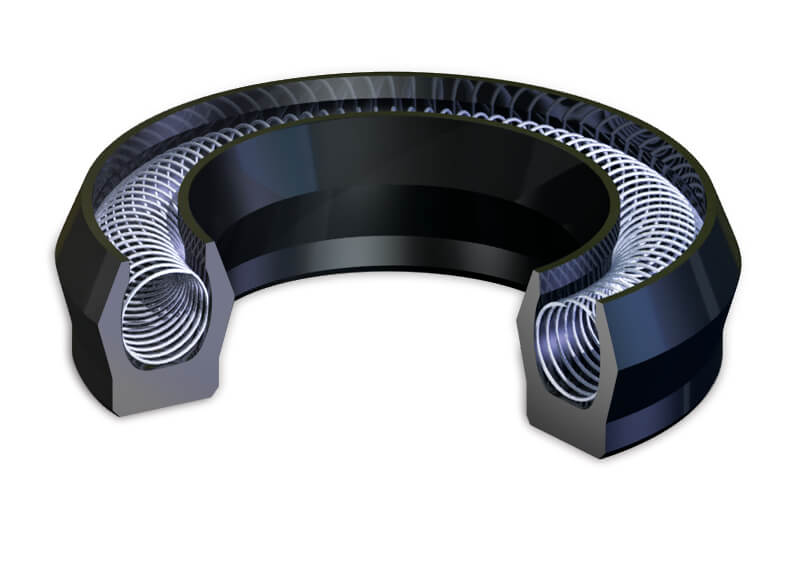

Series 200 Elliptical CoilSeries 200 consists of a canted coil spring which allows for minimal deflection while applying low load. Good for rotary, reciprocating, and static applications where compensation for loose tolerances or a miniature seal is required. |

|

|

Series 300 Helical WoundSeries 300 includes a flat ribbon coil spring with high load versus deflection range which provides extremely tight sealing. Good for cryogenic and vacuum applications at static or slow speed. |

|

|

Series 500 Stacked SetHigh performance, multi-purpose stacked SES and V-Ring set. Accommodates hardware with deep stuffing boxes. |

|

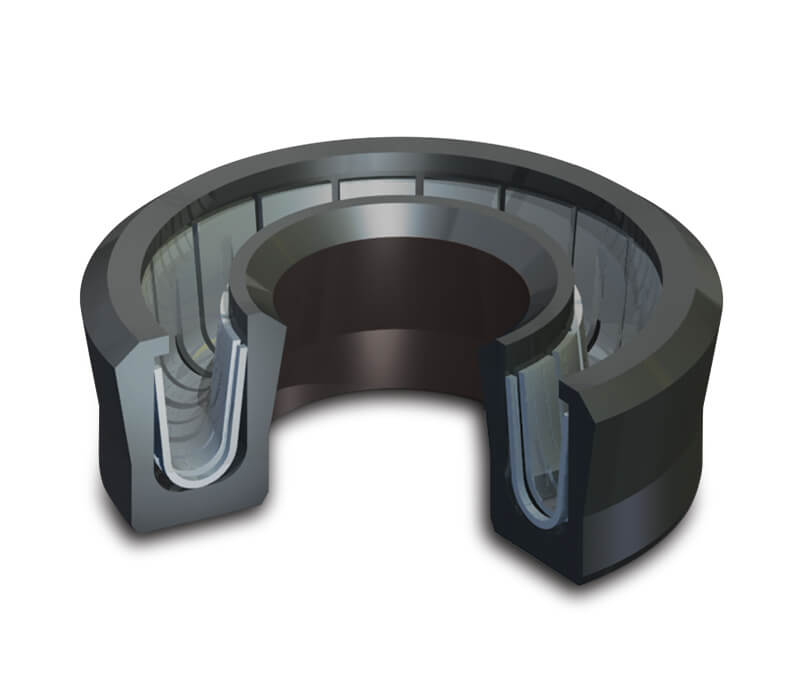

Series 600 Continuous ProfileConsists of a U-shaped, heavy-duty, high-load spring that is best for challenging static sealing conditions. Good for static and slow oscillating motion, particularly under cryogenic and vacuum conditions or where gas leakage is a particular issue. |

Jacket Materials

Chesterton seal jackets can be made from a range of polymers, depending on the requirements of the application. Polymeric material options include PTFE, TFM, UHMW-PE, and PEEK. To suit the needs of specific applications, these can be filled with additives such as carbon, graphite, glass, molybdenum, and other materials.

Spring Materials

Chesterton seal springs are fabricated using a range of high performance, corrosion-resistant metals and alloys based on the application temperatures and chemical requirements. Stainless steel is typical for fluids up to 127°C (260’F) and corrosive applications at lower temperatures. Eligiloy Hastelloy, and nickel alloy materials are used for cryogenic and high-temperature, corrosive flu id environments.