Made in USA in ISO 9001 /AS91 00 Facilities

Kurt Manufacturing

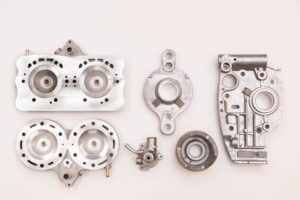

Die Cast Aluminum Parts

- Alloys: A380, A360, and A390

- Machine Tonnage: 450 to 1200

- Part size from few ounces to 30 pounds

- Complete secondary machining in foundry with CNC mills and lathes

- ISO 9001

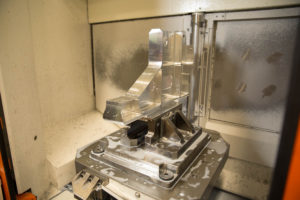

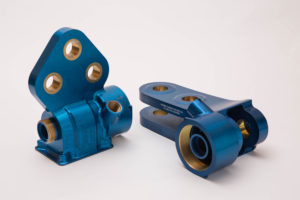

CNC Machined Parts

- Six divisions with over 500,000 square feet of manufacturing space

- Turning up to 36 inch

- Milling up to 36 inch cube

- Stainless steel, aluminum, lnconel, carbon steel, castings and forgings

- Complex assembly

- Nadcap for chemical process and non-destructive testing

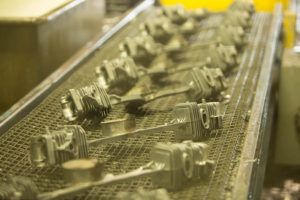

Impact Extrusions

- Form cylindrical parts inexpensively

- Aluminum, Steel, Copper

- Up to 6 inch diameter and 30 inch lengths

- Secondary machining

- ISO 9001

In business since 1946, Kurt Manufacturing is an employee owned contract manufacturing company with a focus on producing components for the Aerospace, Defense, Medical, and Industrial markets. Kurt’s Die Casting division can produce parts up to 30 pounds in weight. Unique to the ISO 9001:2008 certified die casting division is that there are 16 machining centers within the facility available for secondary operations (turning / milling / grinding / assembly). Kurt’s precision machining division is ISO 9001:2008 and AS 9100 certified.

Gallery of some of our workmanship