For over 70 years, Koyo High Precision has earned the trust of high-tech organizations by supplying customer specific high-precision machined metal parts.

Industries served include:

- Medical Equipment

- Semiconductor Manufacturing Equipment

- Industrial Equipment

- Automobile and Motorcycles

Million Production Capability per Month

- We accept small-volume orders, even one piece while still providing mass production of High-Precision

Components to over 1,000,000 units per month - Manufacturing capabilities include 30 machining centers with over 200 CNC machines that provide a production

capacity in excess of 1,000,000 pieces per month

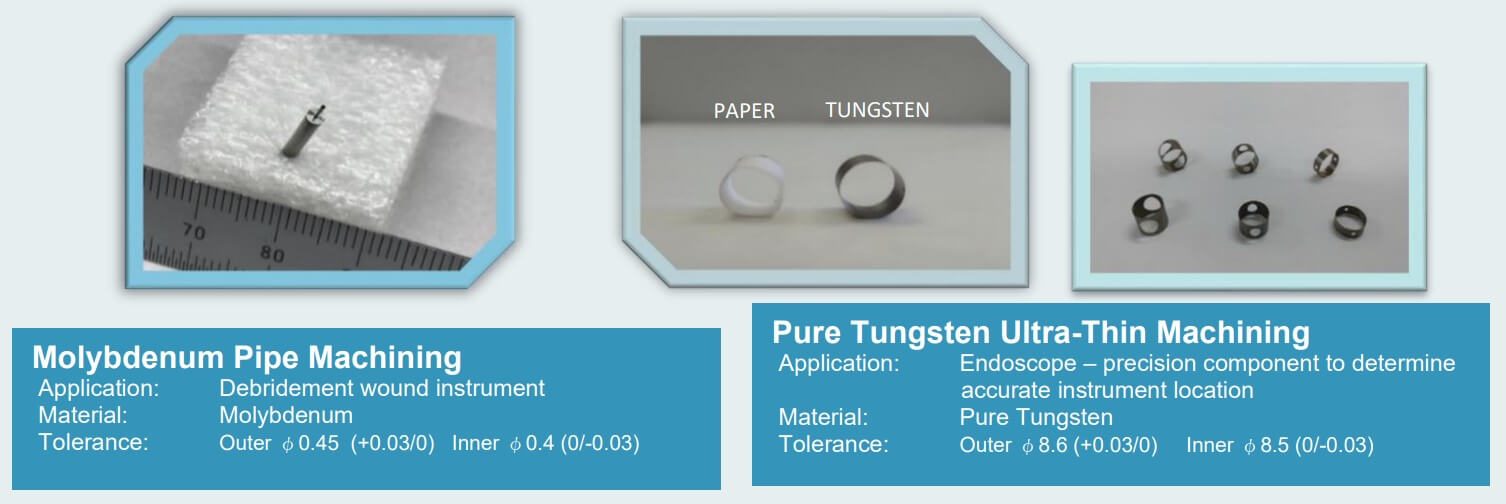

Difficult-to-Cut Materials

- Stainless

- Brass

- Aluminum

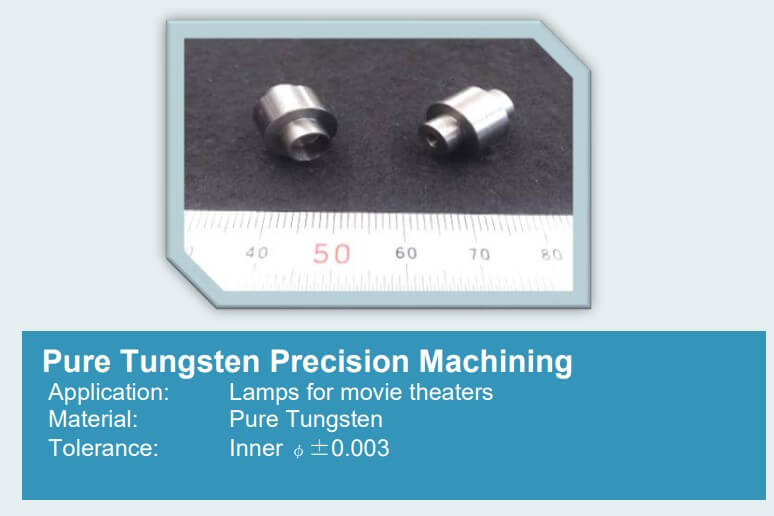

- Tungsten (W)

- MAT21

- Molybdenum (Mo)

- Tantalum (Ta)

- Niobium (Nb)

- Hastelloy

- Inconel

- Permalloy

- Alloy 42

- Kovar

- Nickel

- Silver

- Copper

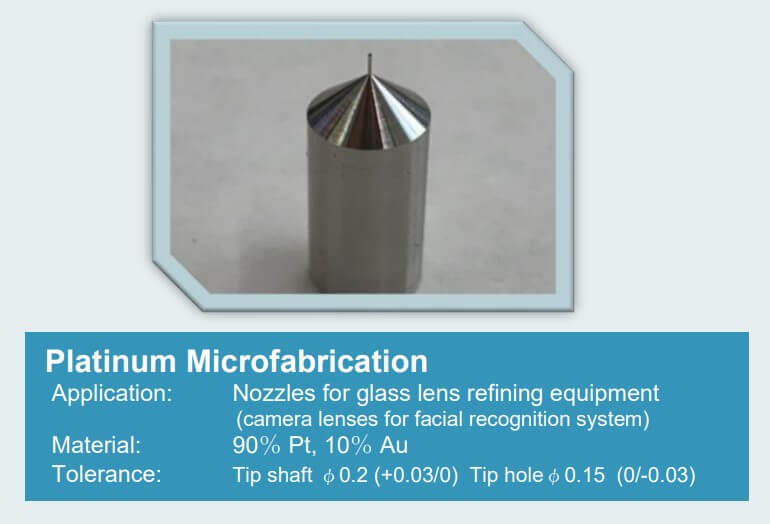

- Platinum

…and many more

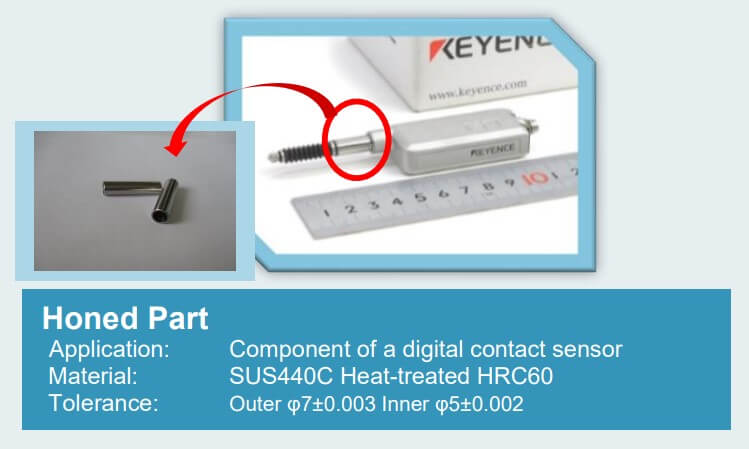

High-Precision Machining

- ±0.003mm (±0.00011″) tolerances on Tungsten

- Nozzle with outer diameter 0.2mm (0.0079″) and inner diameter 0.15mm (0.006″) on Pt

- Through hole φ0.2mm (0.0079″) length 40mm (1.57″) on Hastelloy

Examples of Koyo’s Machined Parts (Unit: mm)

Optical

Medical Equipment

Measuring Instrumentation

Semiconductor Manufacturing Equipment